why Our System eXcels

A higher form of energy

Biomass gasification processes have typically yielded either a low-grade fuel gas, which has insufficient power to be a truly viable energy substitute, or a higher-grade syngas, where the process has restrictive capital costs as well as high energy and resource input requirements. Most of these syngases are heavy with restrictive tars that require further processing, additional energy and more capital investment to remove effectively.

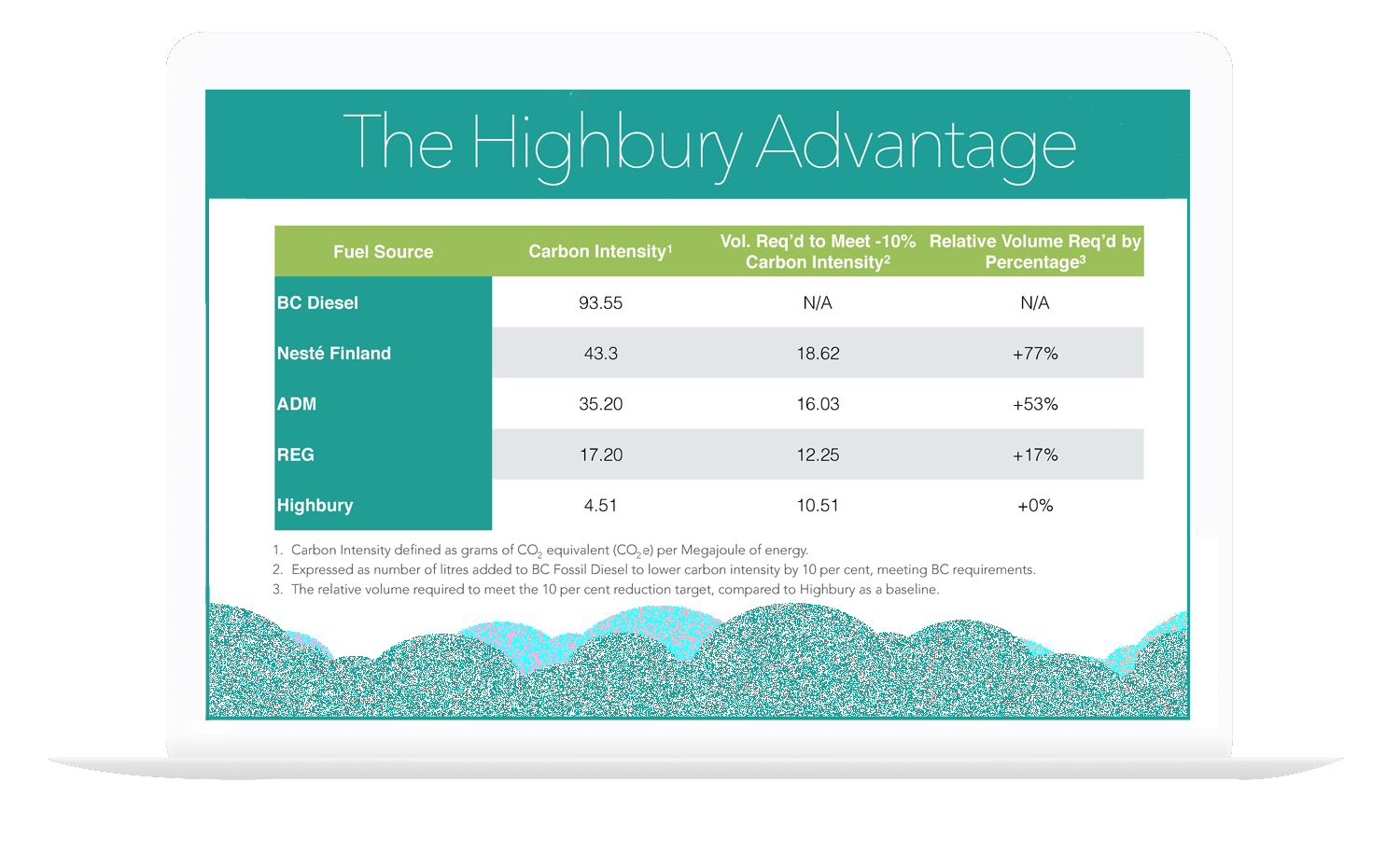

Advantage: Highbury

1. It’s more robust. The Highbury System can process heterogeneous biomass – low-grade biomass including human sewage that would be very difficult if not impossible to gasify in other systems.

2. Up to 40% lower capital costs. Our patented tar reforming catalyst cleans 99% of the tar from the syngas right in the gasification chamber, eliminating the need for expensive, inefficient tar cracking vessels or thermal scrubbers. Eliminating the tar reforming vessels reduces capital costs by as much as 40% – or roughly 40% of the cost of a typical biomass-to-ethanol production plant. On a large-scale plant, that can add up to millions of dollars.

3. Lower operating costs. Because our system runs continuously on its own energy, no external energy source such as natural gas, or combustion medium such as oxygen, is required.

4. Syngas that’s high-BTU. Instead of adding air to the gasifier, a carefully measured amount of steam releases hydrogen (H2) from the water molecules, producing a greater quantity of hydrogen than would otherwise occur. Our syngas production grades have recorded levels approaching 14 MJ/m3 (376 BTU) – comparable to the energy level of natural gas. Air is used only in the separate combustor where residual char is consumed as a source of energy.

5. Syngas that’s clean. Our novel, patented tar removal process will also allow us to manipulate the H2/CO ratio – which facilitates converting the syngas to liquid state if desired.

6. Scalable efficiency. With the Highbury system, a small increase in plant size reflects a large increase in production. Our engineering partner, Vancouver-based NORAM Engineering and Constructors Ltd., has the worldwide design and manufacturing experience to implement our technology at full industrial scale.

The results bear out the design. Syngas from the Highbury system is measurably superior in quality and caloric content than from conventional single-stage gasifiers. Instead of a typical 4.5-5 megajoule (MJ)/m3, our system delivers up to 14 – almost three times more.