Our gasification technology

A revolutionary fuel source

Highbury’s gasifier prototype at the UBC Department of Chemical Engineering in Vancouver, BC.

Producing high grade, low-carbon (LCI) fuels from biomass

Highbury’s gasification technology produces higher grade fuels more economically than competing biomass fuel technologies on the market today.

Import waste, export high value fuels

Unlike other systems, our gasification technology can turn organic waste into the raw material of liquid fuels carrying a low carbon intensity (CI ±5.0) – refinery-ready and fully fungible.

A low carbon intensity (LCI) energy solution for the planet

Instead of adding CO2 to the atmosphere by burning organic waste or leaving it to rot, our gasification technology turns that waste into usable energy – without creating any additional CO2.

Generate profits as well as energy

A full-scale gasifier isn’t just good for the planet, it’s also a boost for your company’s bottom line. With its low capex cost, it can be turning a profit in as little as 4 years.

A scalable, profitable solution to global warming

Some biofuel processes need 300,000 tonnes or more of biomass feedstock a year to work. Sourcing and transporting that amount of material is not always feasible or even possible, especially for smaller operations like sawmills and (smaller) pellet mills. The Highbury process works very efficiently with just 125,000 tonnes input p.a., making it ideal for local farm and forestry operations – while earning extra profits and reducing CO2 output.

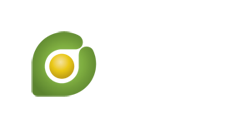

Core Technology

Typical gasification processes using air produce low-grade fuel gas with a nitrogen content of about 50%. Their low-energy-content fuel gases cannot be readily converted to liquid fuels or renewable natural gas. By contrast, Highbury’s dual-bed gasifier produces a high-grade syngas without the need for supplemental oxygen gas. Its syngas is essentially nitrogen-free, and can be converted to high value liquids or gaseous products. Additionally, the gasifier’s patented tar removal system efficiently removes 95+% of tars from syngas, normally the most expensive part of the process. So it can produce a higher purity of syngas at a lower cost.

Feedstock for conversion

Our gasifier is more efficient than traditional gasifiers, and can turn almost any form of biomass – from waste wood to sewage sludge – into extremely pure syngas. Which means Highbury can be very cost competitive with the current and anticipated future costs of biomass feedstocks.

Conversion to syngas

Our gasifier’s patented tar removal system can efficiently remove 95+% of tars from syngas, normally the most expensive part of the process. As a result, it will produce a higher purity of syngas at a lower cost.

Final conversion

Liquids derived from our gasification process will carry a BTU of 36 mJ/l – nearly identical to Suncor Synthetic A crude and other pooled mixed-crude blends, and exponentially higher than liquids from traditional gasifier technologies. Along with its ultra-low Carbon Intensity of (approx.) 5.0, the produced liquid contains aromatics below 1% and sulphur below 1ppm wt. If not converted to liquids, the syngas can be used to generate electrical power in areas where hydro, solar or wind are not viable. It can also be used as direct substitute for natural gas in kilns.